Dynamic Textiles

Thermochromatic materials have been existing for a long time, but utilizing them in wearable projects is not common seen. This blog post is about my research on using thermochromatic pigments to create dynamic textiles for my ITP thesis project My Heart on My Dress.

Materials

Thermochromatic fabrics

The fabrics are pre dyed with thermochromatic pigments.

Pros: the colors are evenly applied on both sides of the fabrics.

Cons: Limited colors and textiles.

Color changing effect of thermochromatic jersey fabrics when heated by heating pad

Thermochromatic pigments

The pigments come in powder format. They can be mixed with screen printing binders or dyeing solutions. They come in different color changing temperatures.

Pros: can be applied onto different fabrics with different methods such as screen printing, painting or dyeing. Different binders can be used.

Cons: need to be applied onto fabrics by users.

Thermochromatic ink

The ink come in different colors and color changing temperatures. Different application methods will need different kind of inks.

Pros: ready to use onto fabrics or papers.

Cons: specific ink applies to specific materials such as paper or fabrics.

Application Methods

Screen Printing

Screen printing creates customized patterns and layering effects. Combining thermochromatic ink with non-thermochromatic ink will create different color changing effects.

Other methods

Dyeing

Brushing Painting

Reversed Color Changing

Most of the thermochromatic ink looses color when heated. To show color when heated, I discovered this method with advice from Maggie Orth:

Using non-thermochromatic ink to print out the pattern, then use thermochromatic black ink to cover them, and then cover the rest of the fabric with non-thermochromatic ink.

Circuit Control

In some of the cases, instead of letting heat change the color of the entire fabric, we want to heat up different parts on the fabric separately. One practical way to do that is using a circuit to control heating pads.

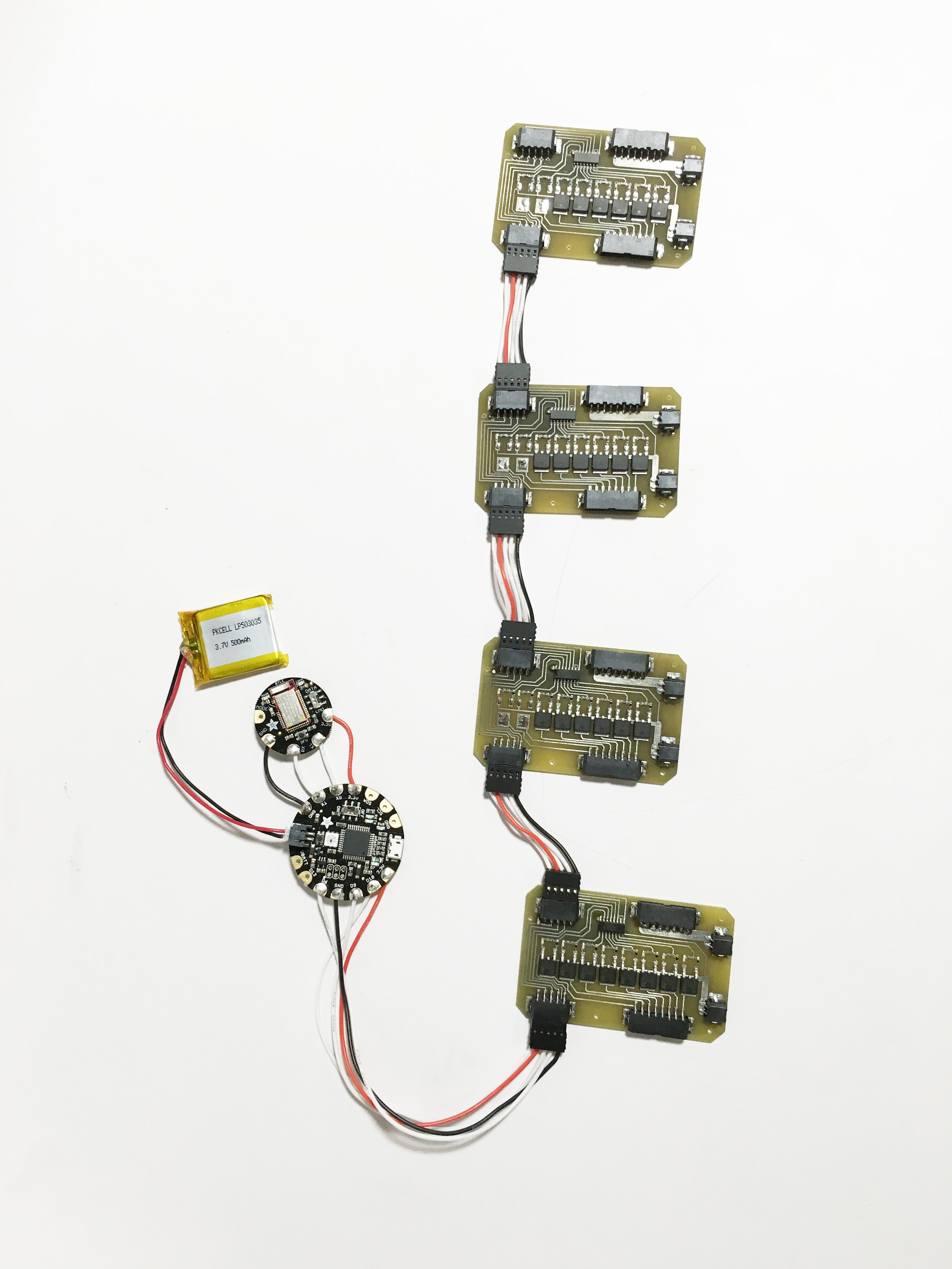

The circuit I designed is wireless and modular. It uses a Flora + Flora BLE Module as central control to receive commands from mobile apps wirelessly through bluetooth LE and control the heating pads individually. Each of the module has an 74HC595D shift register, 8 sets of a mosfet, an LED and resistors to control the heating pads and give signal feedbacks through the LED. I used term blocks to connect the circuits so that I can plug or unplug them to add/reduce outputs.

Here's the breadboard and schematic diagram of one module:

Customized printed circuit boards:

My Heart on My Dress is the project I made with the techniques above. More details are in the project page.